The FarmDroid FD20 was developed with one specific aim; to manage weed control more effectively and sustainably, thereby using technology for the greater good of farmers and planet earth!

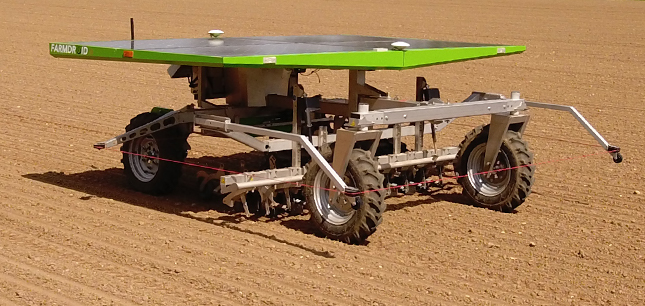

It is an autonomous, innovative field robot that seriously reduces or eliminates labour costs when weeding. All the seeding and weeding is done in an environmentally friendly way. It uses high precision GPS seeding to pin point the position of each seed, making weeding possible both between rows as well as between plants in the row. It is energy independent, powered by solar panels and is CO2 neutral.

The automatic, lightweight, field robot automates sowing and weed removal without causing structural damage to the soil. Headlands and wheelings are relegated to the past and no longer cause reduction in yields.

This revolution in weed management makes investing in a FarmDroid an attractive business case with a return on investment down to as little as two years.

FEATURES & BENEFITS

Solar powered - green technology

The sun is the source of energy for the FarmDroid, making it energy independent. The four solar panels deliver up to 1.6kWh, equivalent to 20 kWh per day and the surplus energy is stored in the lithium batteries. They generate enough power for 18-24 hours of daily operation, depending on weather and working conditions.

The direct propulsion consists of two electric motors, producing a total of 800w. This drives the FarmDroid up to a maximum of 950m per hour and makes it capable of seeding or weeding up to 6ha (approx. 15 acres) per day. There are no emissions, meaning a FarmDroid operates in a completely carbon-neutral way.

Fully automatic - GPS technology

The FarmDroid FD20 knows the location of every single plant. The robot places each seed in a perfect pattern and it knows where each drilled seed is located. This is made possible through the use of high-precision GPS technology. The FarmDroid takes care of sowing and subsequent weeding without need of monitoring via a camera.

Row distance, plant distance, sowing depth, speed, and tolerances can all be adjusted to fit various crops, various types of soil and the farmer’s individual wishes.

The FarmDroid has been developed to be able to handle various crops which means you can use the same machine for e.g. sugar beet and onions. So far, we have experience with sugar beet, fodder beet, onions, spinach, kale, flower seeds, and OSR, and more crops are added continuously. Contact us to learn more about the seeding and weeding possibilities, or if you have a crop that you are considering using a FarmDroid for that we have not listed above, we'd be happy to discuss what's possible.

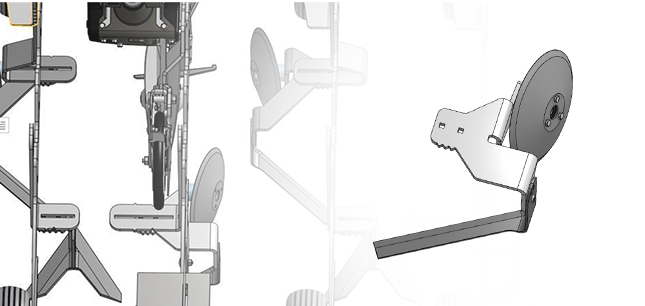

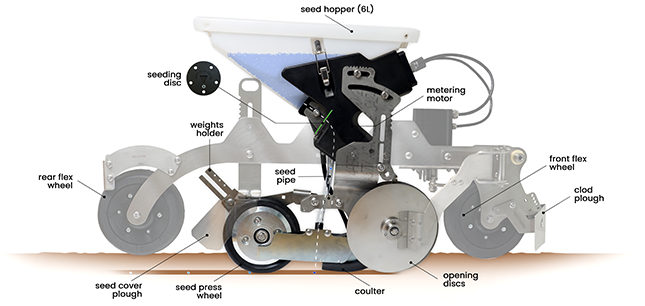

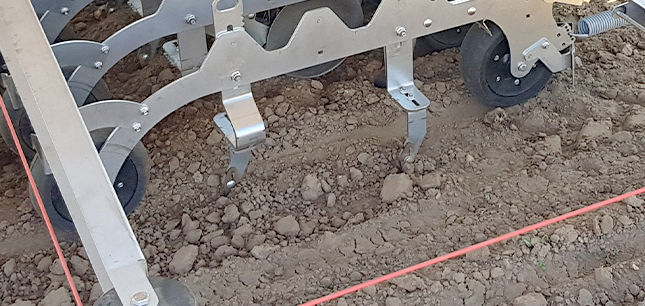

Precision seeding unit

The seeding unit comprises a six-litre hopper, metering unit and double-disc coulter, designed to plant to up to 5cm depth into a fine tilth.

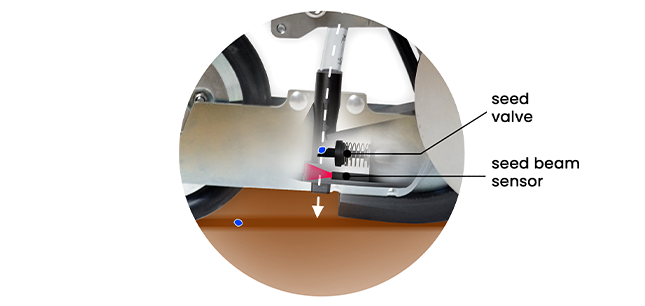

The seeding disc drops the seed onto a seed valve and when traveling across the field the seed valve will open to place the seed into the soil, at precisely the right moment so that the correct spacing for the desired plant population is achieved. This is pre-determined so that the FarmDroid knows where every seed is placed.

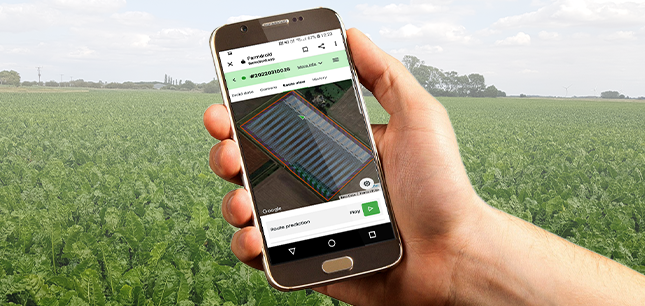

The seed beam sensor that sits below the seed valve counts and monitors every seeding operation. The customer can remotely monitor this via the FarmDroid app on their mobile phone/device.

Compatible with 100+ seed types

+SEED 14 mm SEEDING SYSTEM

FarmDroid ‘seed, weed and spray’ robot receives major upgrades: capable of drilling larger seeds such as maize, beans and peas as well as working faster.

The larger seeding system significantly expands the capabilities of the autonomous solar-powered robot, making it a viable solution for growers who need to drill larger seeds. The development also allows vegetable and salad producers to target the highest value crops and provides options for certain organic operations, some of which would have previously been out of reach.

Whether you're an organic farmer looking to grow maize or a veg grower aiming to enter premium markets, with its ability to operate at speeds of up to 900m/hr the +Seed 14 mm system offers a solid return on investment.

Find out more here

+Seed 14 mm system and upgrades:

- Handles seeds from 0.8mm to 14mm diameter, including irregular shapes

- Compatible with 111 seed types; individual placement, seeding in rows or in clusters

- Larger seed hopper: 7 litres, reducing time between refills

- Faster forward speeds: 720-900m/hr, crop dependent

- Improved weeding precision: Tools can now work even closer to the plant

- Expanded weeding tools: Range of shares and blades to suit specific crops

- Row spacing: 25cm to 90cm

An insert is also available to allow any FarmDroid fitted with the new +Seed 14 mm system to be able to drill smaller seeds down to 0.8mm diameter.

Beans

Maize

EASY TO SET-UP

The FarmDroid works autonomously when sowing and weeding the crops. From the sowing process, the robot knows the position of every seed and therefore knows where it subsequently must weed – and just as importantly: where not too. It operates fully automatically and can be remotely monitored.

A FarmDroid can stop itself whilst working and sends an email or notification to the operator in case of rain or other deviations. This gives the operator confidence and peace of mind when working with an autonomous, remote machine.

Areas for ecological agriculture rise year on year and simultaneously the focus on reducing pesticides in conventional farming increases. Therefore, there is a continuously increasing focus on and need for mechanical weed control in agriculture.

Robot set-up is simple with the HMI control unit:

- Map a field - at setup, the field’s corner points are marked

- Mark any obstacles in the field such as trees, power poles etc.

- Select the A-B line

- Select the working width

- Choose the number of headland passes required

- Select seed placement width - the sowing distance (distance between the crops in the row) and set the sowing depth

- Select ”START”

- Watch the machine at work!

FarmDroid has been developed with the focus on automatizing mechanical weed control between the rows and in-between the plants. This is, in ecological agriculture, most often done by manual labour. The labour costs per hectare are large, the work is exhausting, and a general lack of manual work force in agriculture makes it difficult for farmers to produce economically sustainable crops.

Precise weeding ensures an increased yield

Inter and intra-row weeding! This offers precision weed control both between the rows and between the plants within the rows to ensure that the crop has optimal growth conditions without having to compete with weeds for nutrition and sunlight.

Organic growers across northern Europe – and in the UK – have seen some fairly dramatic results where using the FarmDroid. They’re reporting increases in beet yields of 40-60% over tractor-hoed crops and are putting this down to the combination of precise seed placement and intra-row weed control making for uniform crop development.

Combined with the savings in herbicides, fuel, labour, and machinery costs, the financial argument for a FarmDroid is a strong one, especially as the purchase price and ongoing running costs are a fraction of those associated with the traditional machinery used to do the job.

Blind weeding

FarmDroid uses high-precision GPS technology so it does not depend on cameras or sensors to recognise plants and weeds. Precision during sowing ensures that the robot knows the exact position of every individual plant and therefore it can start the weeding process at a very early stage – even before the crop starts germinating! The process of blind weeding means that weeds do not compete with the crop from the get go.

Protect the soil's structure

The FarmDroid has the lightest footprint possible - good for soil health and the bottom line - headlands aren’t run down with the result that yields are maintained across the entire cropped area.

Seed, weed & spray up to 40ha,

whilst you get on with something else!

- Robotic mechanical weeding

- Reduce labour and fuel costs

- Carbon neutral operation

- Spot spraying saves up to 94% of chemical costs

CROP TIMELINE - ONIONS

Growing onions in clusters

For the first time, 2022 saw a commercial onion grower in the East of England approach their onion crop in a completely new and autonomously powered way – trusting in a FarmDroid.

Before the FarmDroid was put to work, the seedbed in the 8ha field was prepared and then mapped, taking into account natural obstacles to remove them from the cropping area.

Other than checking on the FarmDroid robot by keeping tabs on it via the mobile phone app and topping up the seed hoppers, labour was kept to a minimum. Being solar powered, no diesel was used in the production of these onions!

Below is a timeline highlighting the crops development alongside some of the dates where seeding and weeding took place throughout the 2022 season.

Robotic Mechanical Weeding - SFI Scheme Eligibility

£150 per hectare

If farming in England, you could receive an additional £12,000 per year* (based on 40ha spring crop and a 40ha winter crop) for using your FarmDroid FD20 to mechanically weed your crops. This could be achieved through the Sustainable Farming Incentives robotic mechanical weeding action which pays growers £150/ha.

*SFI payment based on 80ha, e.g. 40ha spring Sugar Beet crop and 40ha winter OSR crop.

FARMDROID MODELS

Share via WhatsApp

Share via WhatsApp